Elon University senior psychology major Jenna Gilder has been seeking assistance for her undergraduate research from the Makerbot Replicator 2—a tool that speaks in a series of whirrs and chirrups.

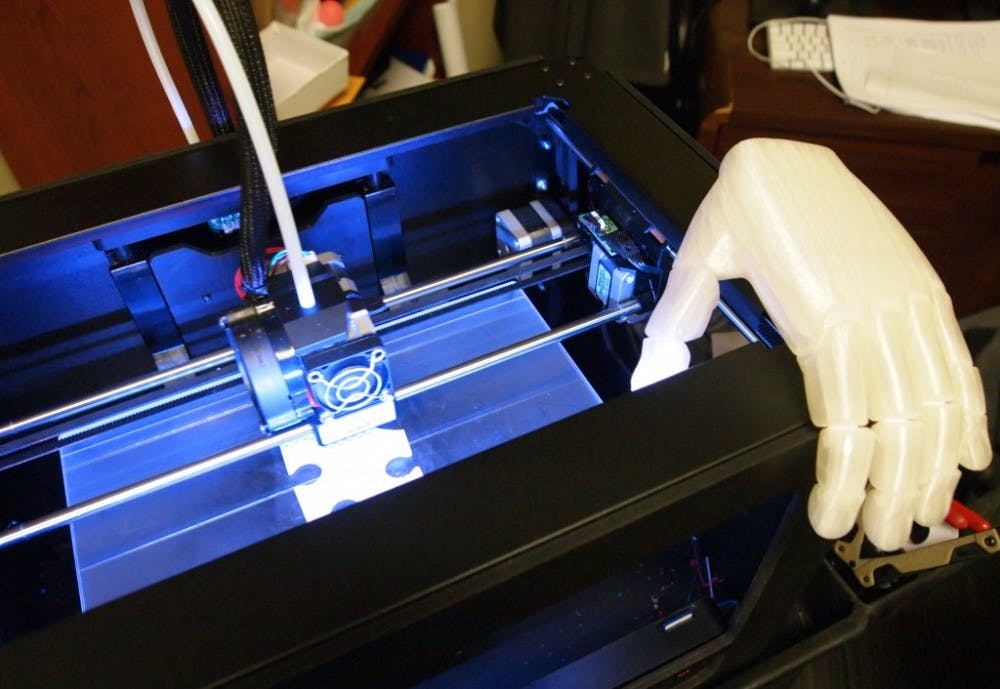

3D printers, like the Makerbot, read a digital blueprint of a design, and the printer head forms the design by pouring heated material (usually plastic) in successive layers.

First, plastic filament, the 3D equivalent to paper, is threaded through a tube in the printer. Next, a 3D image loaded onto an SD card is read by the printer. When the command to print is given, the filament is heated until it is near liquid, and the printer head slowly dispenses the molten plastic in successive layers on a printing plate.

As the product comes in contact with the room temperature, it re-solidifies and returns to its former hard plastic state. Once complete, a thick card stock or razor blade is used to remove the object from the printing plate. Finally, the idea developed on a screen is a tangible object.

The time it takes to print a design varies by its intended size and intricacy. According to Dan Reis, an instructional technologist in the Teaching and Learning Technologies (TLT) department, the coat hanger and brain featured in the picture below took around 45 minutes to create and the robot took around 30 minutes to create.

3D technology used in research

Gilder, along with Assistant Professor of Education Heidi Hollingsworth, is examining the amount of attention a child diagnosed with a developmental disability gives an adapted puzzle piece versus a standard size puzzle piece.

The adapted puzzle piece, created using Elon’s new 3D printers, is thicker than a standard puzzle piece. Both puzzle pieces are in the shapes of elephants from a Danish children’s puzzle.

Gilder hypothesizes that children diagnosed with a developmental disability will focus more on the adapted puzzle and will be more successful at completing it. This, Gilder hopes, will provide insight into the toy needs of children with Autism Spectrum Disorder.

“Ultimately, we hope that this will better allow for play success,” Gilder said.

The elephants used for her research were ideas that were made tangible through the designs created on the Makerbot.

3D printing technology has played an integral role in Gilder and Hollingsworth’s study, allowing them to alter the thickness and size of the pieces to create a puzzle adapted to the specific needs of individuals with developmental disabilities and fine motor deficits. The technology also allowed them to make an identical standard puzzle to help make a more informed comparison.

Though it was Gilder’s first time using a 3D printer, she said the process did not intimidate her, despite having to wait three and a half hours for each of the larger pieces to be printed.

“It was very interesting to watch,” she said. “The idea that these puzzle pieces were created from an image on the computer was just astounding.”

Students experiment with Makerbot

Students and faculty from other academic areas have also incorporated the new technology into their studies.

Engineers at Elon have been using the printer to design functioning models of rockets. Entrepreneurs in the Love School of Business have been printing prototypes of product concepts. Students in environmental science have even printed out their own lab equipment. 3D printing technology has even been incorporated into syllabi.

Last spring, when the Computing Sciences Department purchased a 3D printer, computing sciences department Chair Joel Hollingsworth co-led an “Interactive Art” class with Michael Fels from the art department.

The class, a combination of sculptural designing and computation, was the first computer science class that focused on 3D printing technology.

“At the beginning, some students seemed a little intimidated [by the new technology],” Joel Hollingsworth said. “But by the end of the term, they were doing so many incredible things with it.”

Students designed and printed kinesthetic sculptures of various forms, fusing the creativity of art with the technological innovations of computer science.

Junior engineering major Kaylin Hunter worked closely with Joel Hollingsworth and said working with 3D printers holds more than just an academic value.

“It provides a new way to think about creativity and art,” she said. “Art is no longer just something you can make with your hands but something you can design and print.”

Reis and Michael Vaughn, another instructional technologist, said the value behind the accessibility of the 3D printers is they serve as a simple and inexpensive step in the creative brainstorming process.

“Rather than having to print thousands of objects in order for something to be economically viable, you can now print one idea at a time,” Reis said. “This opens up so many opportunities for collaboration in the creative process.”

Vaughn stressed that while 3D printing technology is being used for revolutionary purposes like printing skin, kidneys and replicas of beating human hearts, it can also be used for other purposes, including pure curiosity.

“You can really go whatever direction you want with the technology,” he said. “For example, before the iPhone 6 was released, we printed a model of it just to get a sense of how the new size fits in your hand.”

Investment in creative technology

Aside from departments’ individual 3D printers, Associate Dean of the School of Education Anglea Owusu-Ansah secured a common 3D printer in The Oaks Commons for Elon’s first Mobile Maker Cart using a university grant.

The cart hosts a variety of devices and equipment with which students may experiment, including a 3D scanner that turns objects in the real world into computer models that can be manipulated; an Arduino- a small “robotic brain” that allows computers to interact with the physical world; and Makey Makeys that turn everyday objects such as bananas into touchpads.

Hunter, who is part of a select group of trained students who monitor the usage of the equipment, said the cart is currently only available to Oaks residents and cannot leave The Oaks unless a professor checks it out. Students can check it out either for 24 hours during the week or for the weekend for no fee, granted they have attended a training session beforehand.

“We’re really excited to continue to get more 3D printers and have the use spread throughout campus,” Hunter said.

But while the Mobile Maker Cart is a step to providing students access to innovative technology, Reis and Vaughn have been exploring ways to unite larger groups of people under the banner of technological creativity.

One specific option they have been considering is hosting a Makerspace on campus, a space where people come together to create with technology. The physical space would host more advanced technology and provide students with greater access to 3D printers.

Since last April, Reis and Vaughn have been meeting with an interest group of students, faculty and staff to discuss the possibility of implementing the space on campus. The area would require a large amount of physical space suited for the requirements of the equipment.

They stressed that in order for any progress to be made, excitement, support and interest must be generated.

“Elon is a place where if there’s a good idea, it will happen,” Reis said. “If students want this, they should say so.”

Vaughn said the impact and usage of the technology, especially that of 3D printers, transcends the boundaries of different disciplines.

“There isn’t a single academic area, personal interest or industry that couldn’t benefit from this technology,” Vaughn said.